The craftsmanship of wedding bedding fabrics, and how to choose fabrics!

Perhaps you have already given thorough consideration when getting married, eagerly awaiting the arrival of a happy life. But have you understood these things before getting married? As a necessity for married life, bedding is crucial. To help everyone better understand wedding bedding fabrics, here, our editor will introduce the craftsmanship of wedding bedding fabrics and how to choose wedding bedding fabrics.

Craftsmanhip of wedding bedding fabrics:

Reactive printing on 40-thread-count twill cotton: Twill cotton is a method of fabric manufacturing. Currently in China, home textiles, especially bedding, mostly adopt a two-over-one or three-over-one twill manufacturing process. This process results in a fuller surface of the fabric, which is easier to open and set during the printing and dyeing process, meaning it is less likely to shrink, as we often say. Twill cotton has a higher density than plain weave fabric, consumes more yarn, and has better wear resistance. It is mainly stronger and its shrinkage rate is easier to control compared to plain weave. Reactive printing and dyeing is a dyeing technique that produces finer and brighter colors that do not fade. This printing and dyeing process has high requirements for hardware environments such as machines and water quality, so it is not something that ordinary small factories can achieve.

Shopping for wedding bedding fabrics:

Sanding and printing: It is also a type of printing. In the post-processing stage, this fabric undergoes sanding treatment to give the surface a certain velvet-like texture, enhancing the hand feel of the fabric. So what is sanding? Sanding, also known as velveting, refers to the process of using a sanding roller (or belt) to create a layer of short and dense fluff on the surface of the fabric. It can produce fluff on both warp and weft yarns, which is short and dense. The velvet surface is smooth, with a full and soft hand feel, rich in velvet texture, soft luster, and no iridescence. The sanding fabric is fluffy, thick, and has good warmth retention performance. When falling asleep on a cold night, there is no cold feeling like when other Cotton Fabrics come into direct contact with the human body. At the same time, it has the advantages of no pilling and no fading. The weight of a set of sanding four-piece set is twice that of an ordinary four-piece set.

Gongduan fabric: It is woven with a satin weave structure, with a conventional warp and weft density of 173*124CM, which is a fine-combed and dense fabric. It has a soft texture, smooth surface, good elasticity, and excellent breathability. It was once named after being presented as a "tribute" to the emperor. Firstly, the fabric itself requires a high density, which requires a lot of yarn. Secondly, the most important thing is the mercerization during the printing and dyeing process, which increases the brightness and softness of the fabric. This kind of fabric is relatively smooth and has a good hand feel. It requires excellent craftsmanship. This product is 60-thread-count.

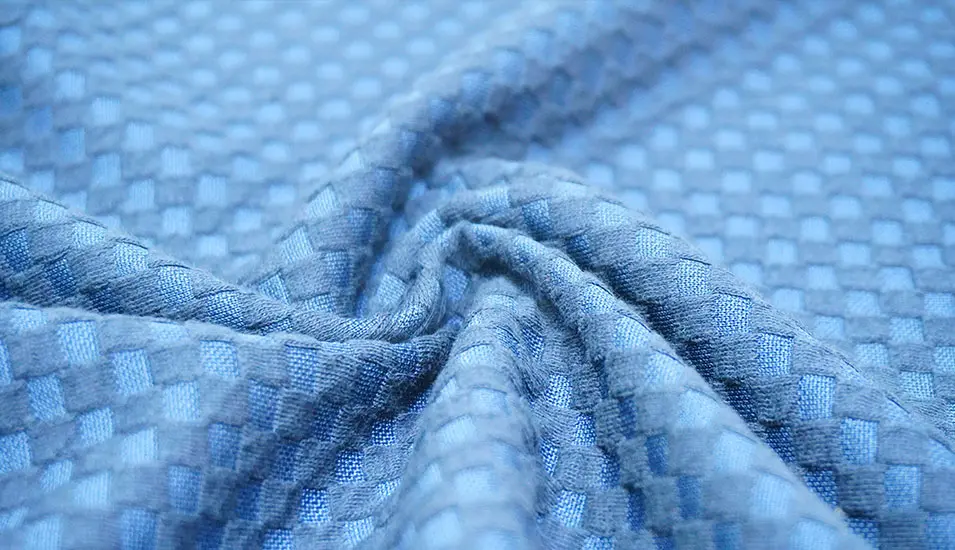

Jacquard fabric: High-count, high-density cotton jacquard bedding is professionally designed based on cultural differences between China and the West. The products are delicate and noble, with a smooth feel, bright colors, exquisite comfort, moisture absorption, and breathability. They are woven using extra-wide rapier looms and extra-wide shuttle looms, with fine yarn counts. In layman's terms, Jacquard Fabric is woven directly through the loom, which displays different parts of the pattern through various weave structures. The pattern of jacquard fabric has a strong three-dimensional effect and rich layers. Jacquard fabric generally belongs to high-count, high-density fabrics, with a soft feel and good glossiness.

Gongduan jacquard: Based on the satin weave, it is woven using the jacquard technique, utilizing two or more different weaves, or combining yarns made from different materials, to create layers and achieve the desired design effect on the surface pattern. The processing technique involves weaving first and then dyeing. The product features not only retain the superiority of Gongduan, but also exhibit more layers and variations, with colors and textures that are more beautiful and pleasing to the eye than pure Gongduan.