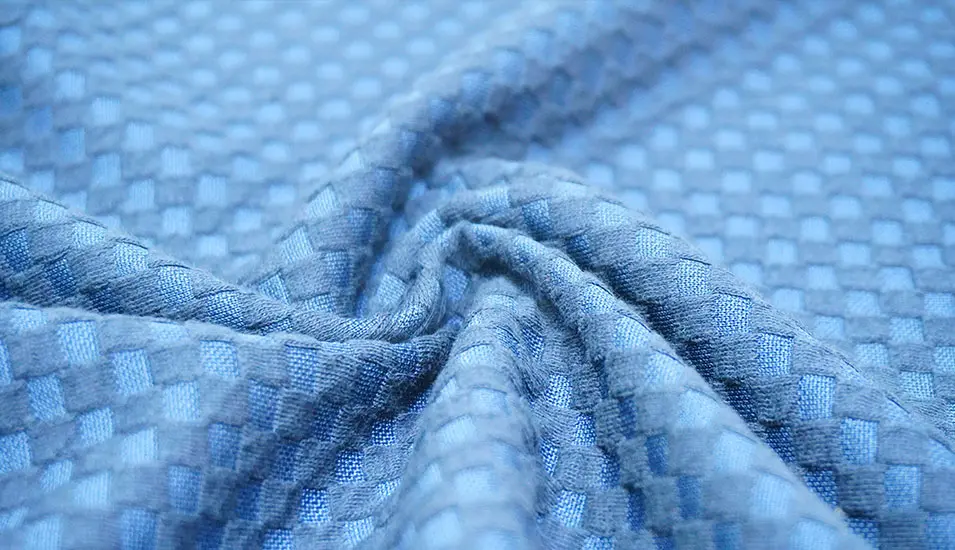

The development trend of new knitted fabrics!!

In today's social development, where people pursue perfect physical and mental health, environmental protection, and fashion trends, there is an unprecedented increase in the requirements for Clothing Fabrics and taste. Given that everyone demands such fabrics, knitted fabric companies will also cater to the current fashion trends, developing and designing new types of knitted fabrics to ensure the sustainable development of knitting companies.

Next, let me talk about the development trend of knitted fabrics.

For weft-knitted novel fabrics, apart from the transformation of the knitted fabric's organizational structure, it is also essential to utilize innovative Textile Materials to collaboratively develop and design novel fabrics. For instance, modal and Tencel cotton yarn, which became popular in 2002, are now widely replaced by soybean fiber, bamboo charcoal fiber, corn chemical fiber, and diversified chemical fibers. All of these are novel raw materials.

Now that the new raw materials have been successfully developed and designed, the next challenge is for the knitting company to determine the design style of the fabric when it is developed. This is a problem that the knitting company needs to accurately position. Another issue is how the printing and dyeing company can cooperate with the knitting factory to develop and design new fabrics. This also needs to be discussed together. The production of each new fabric inevitably involves small and medium-sized samples, trying to achieve the best practical effect of the fabric. The initial investment and revenue cannot be equated, and there will be losses to some extent. However, it is hoped that in the future, hard work will naturally lead to gains. But not now, only when the technology is perfected and mass production is achieved will happiness be tasted.

In the post-processing printing and dyeing stage, due to the thin fabric, it is very easy to get hooked and damaged. Therefore, when using the printing and dyeing cylinder, care must be taken. Also, if the cotton yarn is fine, undoubtedly, super strength is not as good as coarse yarn. The support force during printing and dyeing should be moderate, and the application of modifiers should also be moderate, trying to avoid harming the connective tissue as much as possible, drawing an ultimate conclusion for the development trend of new fabrics.